How traditional medical equipment packaging meets the challe

Release: Hexiang Packaging??Time:2021-09-14Traditional packaging rules such as cost-cutting, flexibility and vividness are gradually affecting the field of pharmaceutical packaging. Since medical equipment does not need to be on the shelf, people in the past often only paid attention to the performance of the product and seldom paid attention to the packaging. However, the increasingly fierce market competition has made some packaging rules widely used in other product fields have a subtle impact on pharmaceutical packaging. With the rapid increase in health care costs, all departments in the pharmaceutical supply chain have to cut costs accordingly. They continue to improve labeling technology and try to write as much product information as possible. In addition, on-demand printing technology has brought great flexibility to the packaging production line. Perhaps the most compelling aspect of the pharmaceutical packaging cost reduction strategy is packaging automation. Pharmaceutical packaging is a labor-intensive industry, and many operations need to be done manually. Converting rigid packaging into flexible blister packaging, especially in the case of large-scale operations, using a form-fill-sealing packaging machine or other automatic packaging machinery, which greatly saves packaging time compared to manual operations. Harold Miller, director of PACE Solutions consulting firm and former director of packaging at Johnson & Johnson, said: "It is clear that a large amount of cost savings comes from the packaging of high-volume products, mainly formed, filled and sealed packaging products-a soft blister or a hard blister. This is not only It saves materials, and the mass production of products makes the packaging shift from manual or semi-automated to fully automated. Secondly, the use of squeeze vacuum machines greatly saves labor costs. "The change from rigid packaging to flexible packaging can be achieved through redesign. To complete, for example, blister cardboard trays are much cheaper than rigid trays with lids.

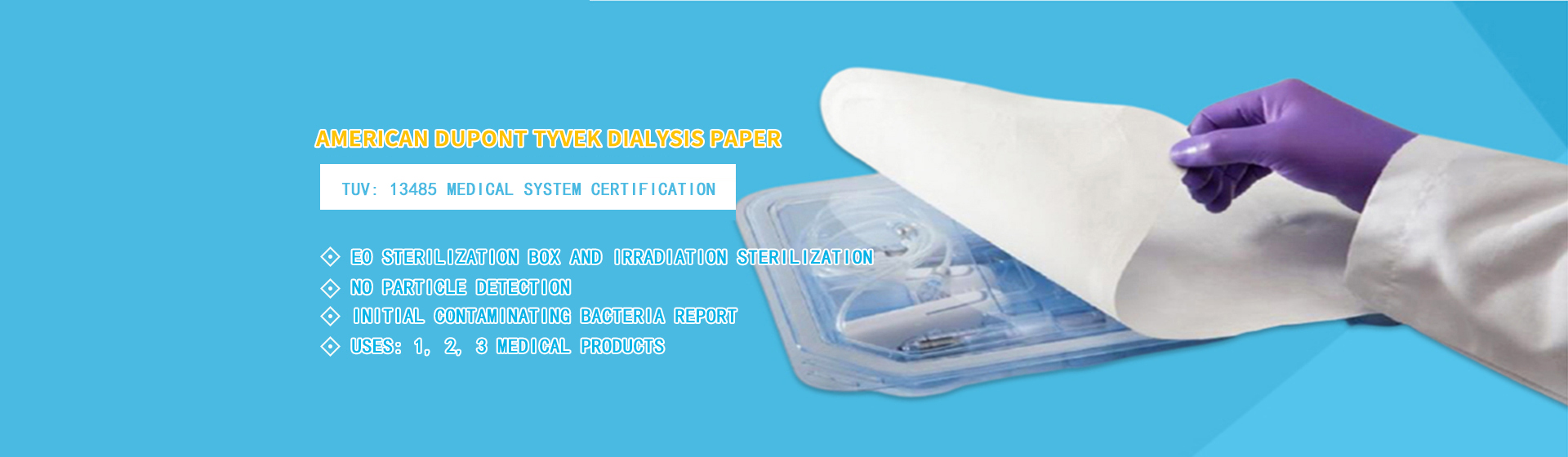

Material strategy Another effective way to reduce costs is to reduce the consumption of high-priced materials, and lower material standards (Downgauging) have therefore become very popular. But many companies have reached the limit in this regard. There are still many companies that reduce costs by reducing certain steps in the processing process, such as peelable coatings. Many medical packaging, especially those that have been sterilized by oxyethane, are sealed with porous materials, and the sealing material is torn off from the side, so it is necessary to ensure the cleanliness of this process. The tearable material must be coated on its surface with a special polymer sealant. However, adding a protective coating to this tearable material adds another step to the medical packaging. Some film processors prefer to coat directly from the bottom and seal with non-breathable materials, which greatly saves costs. The packaging department of Cook's supply center uses a section of aseptic packaging welding for syringes, catheters and other medical devices. The welding point is on the protruding part of the inner layer of the medical device tray, so the tray will not fall off during the diagnosis and treatment process. The Ava-Tex bone glue syringe produced by Cardinal Health is used to treat bone diseases caused by osteoporosis. It is packaged in a thermoformed tray, and it can also be equipped with related devices according to different needs.